Responsible partners: SerQ (Portugal) and Cesefor (Spain)

Description: Experiment nº4 aims to assess the mechanical performance of CLT-concrete solutions under bending stresses using local softwood species. These results follow the Experiment nº3 results. The following steps were established:

- Theoretical design based on codes (e.g. CEN/TS 19103:2021);

- Production of CLT elements at laboratory facilities (Fig. 1);

- Concrete pouring on CLT elements (Fig. 1);

- Bending tests following EN 408.

Figure 1 – Production of CLT at SerQ facilities (left) and concrete pouring (right)

Both maritime pine and radiata pine were considered for CLT production at SerQ and Cesefor facilities. Due to limitations regarding production capacity the specimens (CLT-Concrete) had the following dimensions:

- Length: between 2.5m and 3.0m;

- Width: between 200 mm and 300 mm;

- Thickness of CLT: 90 mm (3 layers of 30 mm each);

- Thickness of concrete: 60 mm;

- Type of concrete: i) standard concrete; ii) concrete with steel fibres (Fig. 2);

- Connections: i) inclined notches; ii) perpendicular notches; iii) screwed connection.

Figure 2 – Concrete with steel fibres

Figure 2 – Concrete with steel fibres

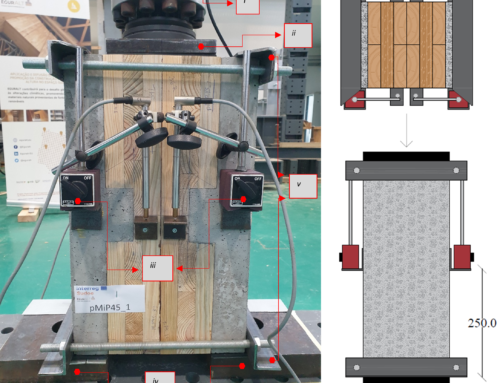

The main goal is to determine the mechanical performance (4-point bending test with a span of 18h) (Fig. 1): i) effective stiffness; ii) load carrying capacity and iii) slip modulus. Despite that, non-destructive tests were carried out to determine both longitudinal and transversal natural frequencies of vibration (before and after pouring) (Fig. 1).

Figure 3 – CLT-concrete specimens test layout under bending

Figure 4 – Non-destructive tests on CLT-concrete specimens

In the case of radiata pine specimens, 5 specimens were tested in each connection configuration (concrete with steel fibres), being also possible to compare a notch configuration behaviour with a standard solution (timber beam with concrete layer).

Within maritime pine specimens, a total of 18 specimens were prepared varying: i) the length of the notch (150 mm and 90 mm); the type of the notch (perpendicular and inclined); iii) the type of concrete (standard concrete and concrete with steel fibres).

Results are still being processed. However, some comments on radiata pine specimens can be presented:

- Specimens with screwed connection had a failure mode governed by shear of connection (5/5 specimens) while specimens with notched connection had a failure by shear at the connection in 4/5 specimens. One of the specimen’s failures was given by bending (Fig. 5);

- Notched connections showed higher strength and stiffness than screwed connections (72% and 34% respectively);

- Screwed connections showed a ductile failure whilst notched connections showed fragile behaviour;

- The slip and uplift between CLT and concrete was negligible for notched connections.

Figure 5 – Failure modes of CLT-concrete specimens